Secop at Chillventa 2024

Hall 7A, Booth 228

As anticipated in the article published on last week, the Secop booth will feature five key areas:

In the Medical Solutions area we showcase our latest innovative cooling solutions for medical storage and transportation from standard pharmaceutical applications to ultra-low temperature needs as well as solar-driven solutions.

MN13UVULTM and MS18UVULTM are electronically controlled compressors tailored for medical applications, and they offer high efficiency in a robust design able to withstand severe applications in ULT conditions. They have been optimized for R290 and are also ready for R1270.

The compressors come with the latest generation of multi-voltage controllers featuring speed control through Adaptive Energy Optimization (AEO), frequency, or serial communication. These multi-voltage controllers can be used for all voltages and frequencies globally. What’s more, they offer a wide range of features also for use in cascade systems including ULT applications and are extremely efficient in a robust. Secop’s dedicated range of electronically controlled compressors optimized for hydrocarbon refrigerants make it possible to design low GWP and low energy consumption cabinets for a new generation of green and efficient medical cold chain devices.

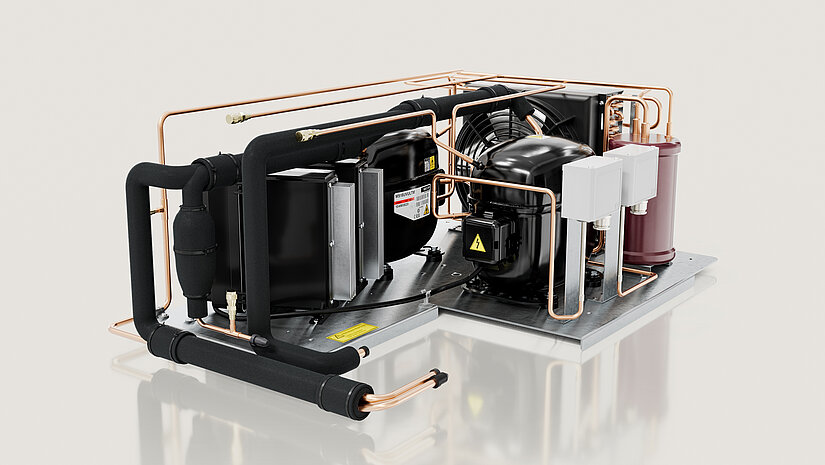

At Chillventa, the ULT cascade condensing units for mobile applications will be on display. These units have been developed for transporting vaccines including under ULT temperatures. They feature two MP2UVULTM DC compressors designed for medical applications that achieve top performance for battery-driven medical boxes and guarantee ULT stable temperatures even in severe ambient conditions. Secop has also developed an AC ULT cascade condensing unit optimized for storage ULT freezers. Two MS18UVULTM medical variable-speed compressors for the low stage (R170) and high stage (R290) maximize the performance of ULT systems while offering minimal energy consumption and maximum robustness.

At the Chillventa booth, visitors can also see firsthand a solar direct drive application powered by a new generation of SDD units. This innovative solution has been developed with the new BDN compressor (the medical variant MB3CKV of the BDN visible in the Mobility Solutions area) and a new AC/DC controller designed to satisfy the new WHO specifications. The new SDD unit has been optimized to offer maximum cooling performances from the new generation of photovoltaic panels and also to from a connection with an unstable AC grid.

The innovative AC/DC interface unit supports off-grid and weak-grid connections in remote areas with unstable power supplies, since the new generation of the power management module has been specifically designed for connection to both DC photovoltaic panels or AC grids. An additional 24 V DC output is available for data loggers, monitoring devices, USB chargers, and external auxiliaries.

The new SDD Power Management Module designed in combination with the new BD Nano MB3CKV compressor offers premium cooling performance with excellent efficiency. It is the perfect choice for off-grid and weak-grid vaccine refrigerators, solar off-grid coolers and freezers, and ice bank refrigerators.

If you are interested in discovering more, there will be a seminar in Hall 7A on Tuesday, October 8, from 1:40 PM to 2:00 PM [Hall 7A/7A-638] where the New Solar Direct Drive solution will be presented by Marc Fisher from the Application Unit and Helmut Grainer from Business Development.