Isobutane (R600a) and Propane (R290)

In chemical terms, hydrocarbon (HC) is an elementary compound composed of hydrogen and carbon that occurs naturally in the environment in crude oil, natural gas, or coal. It is a non-toxic and environmentally friendly alternative to fluorocarbon refrigerants (CFC/HCFC/HFC) which are harmful to the environment since they have been linked to ozone damage and the greenhouse effect. In addition to their environmental benefits, hydrocarbons are cheaper than synthetic refrigerants since they are produced as byproducts of gas and oil. HCs operate at almost the same temperatures as HFCs yet with lower charge. Good thermodynamic and physical properties make HCs an energy-efficient solution.

Low Global Warming Potential (GWP)

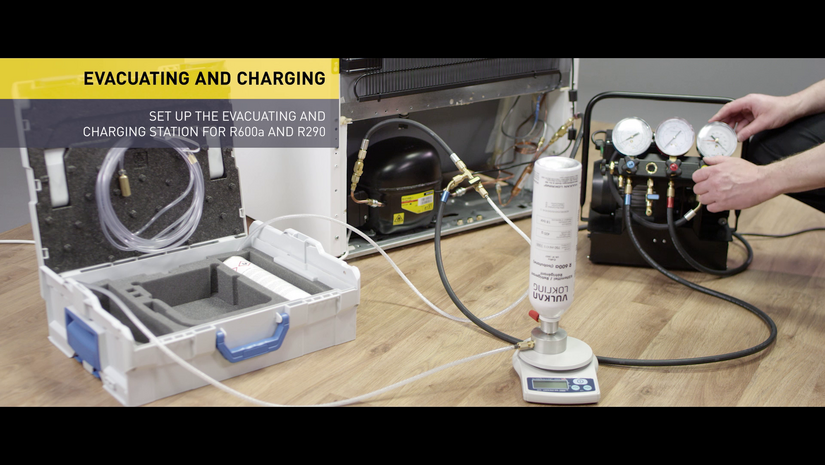

Hydrocarbons have a low GWP, zero ODP and, according to safety standard ASHRAE 34, are classified under the group A3 – highly flammable with low toxicity. Since they are flammable with a potential consequence, safety precautions described in various international and national standards must be considered during the design, assembly, operation, and maintenance.

Isobutane (R600a) is widely used in smaller applications such as home refrigerators, freezers, minibars, automotive, and maritime appliances. Propane (R290) on the other hand, is commonly used in commercial refrigeration for food service and retail, merchandisers, heat pump, air-conditioning, and medical applications.

Refrigerants Position by Secop | Application Guideline for R600a & R290